I built this ignition system because the B3 distributor would not fit in my RWD application. So far it has been trouble free for the past 18,000 miles. I cannot make any claims of performance increases of better fuel economy because I have nothing to compare it to. The only benefit I can claim is the ignition system is more or less maintenance free. Figure this project will take a week or so to build.

This system may fit other B engines and is not limited to the B3.

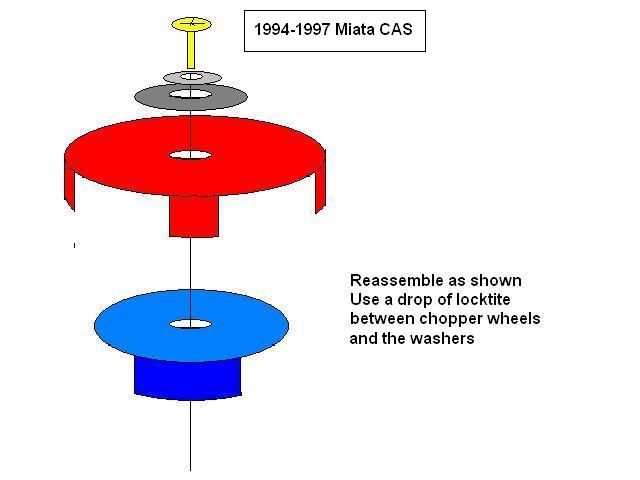

Miata CAS (Crank Angle Sensor)

Saturn S series coil pack

Saturn S series coil pack wiring pigtail

Saturn S-1 series ignition wires (single cam engine)

Custom circuit board that you build

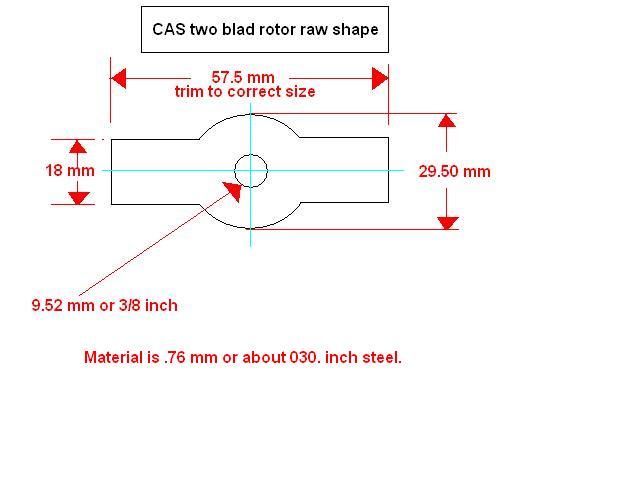

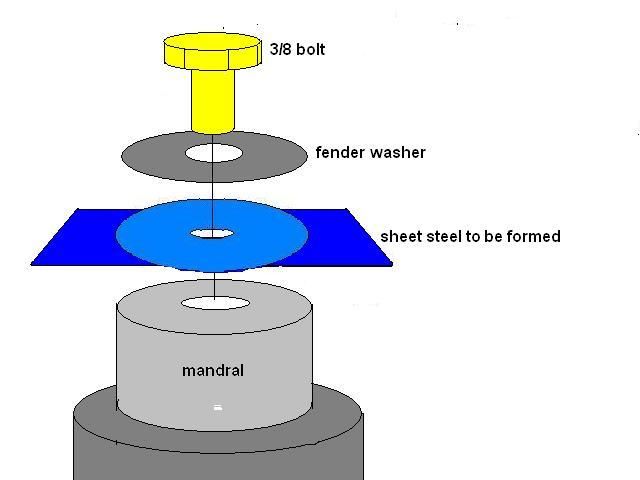

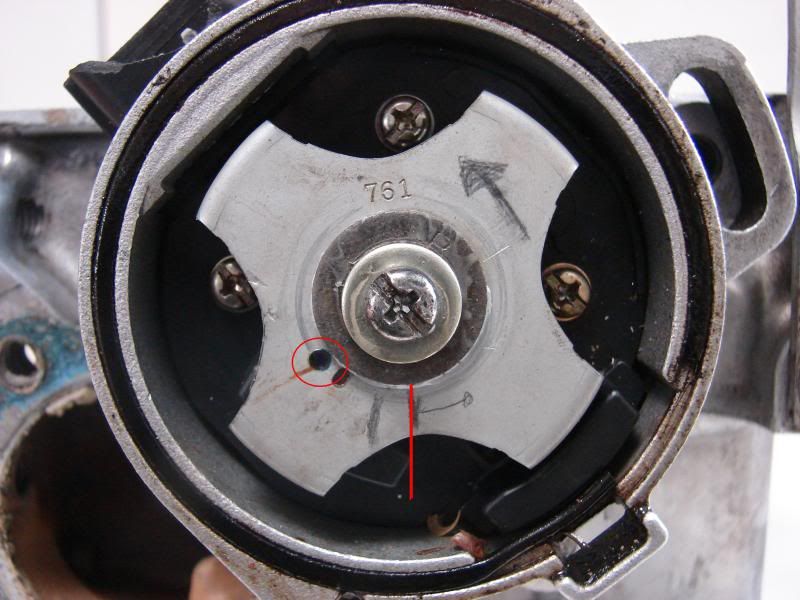

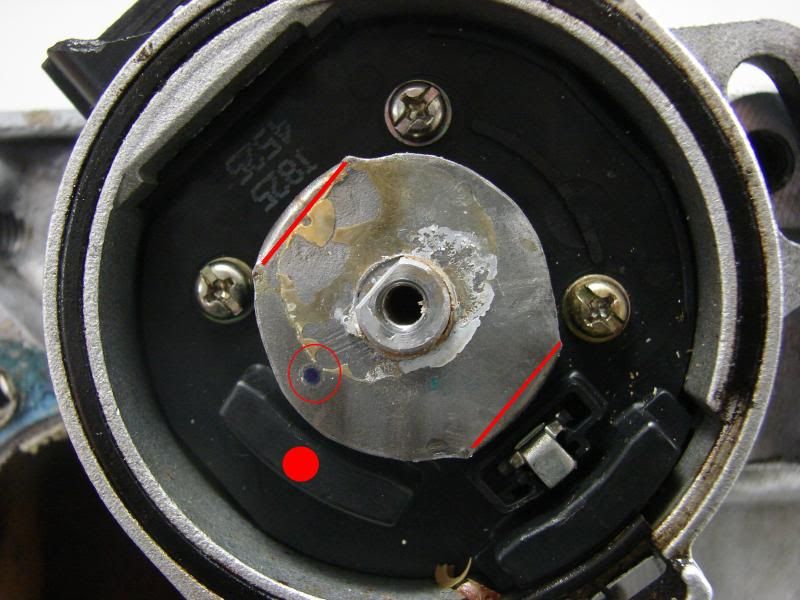

New internal CAS rotor that you fabricate.

* Miata CAS wiring pigtail or an extra fuel injected festiva distributor wiring pigtail.

Tools:

Hand tools.

Cutting tools

electrical tools

Dremel with thin cutting wheels.

Soldering iron

files

This system was originally built to work with the stock Festiva ECM and it will work with Megasquirt. Unfortunately I don't know the RPM limit (if any) but it worked well at WOT on the B3. If you have a factory tachometer in your Festiva I dont know if this will upset the tach or if the tach will continue to work.

Before I get into the nuts and bolts of this project, let's talk about parts. Short cuts may be possible but in general you can expect trouble free operation if you use the parts I recommend.

The coil pack should be off of a Saturn "S" series car built between 1996 and 2001. Others may work, but Saturn parts are dirt cheap at PnP. The coil pack that you want to use needs to be "dumb" and needs to have the amplifiers (ignitors) built in.

My car uses 1994 miata coilpacks, but I don't recommend using them. They are expensive and rare. I wired my car to use both the saturn and miata coil packs. I ran the car with both types of coil packs and eventually chose the miata coilpacks because they will allow the Miata tachometer to work.

The ignition wires are important, See if you can grab "stock" Saturn wires from the PnP. Stock wires have "Packard" written on them. Aftermarket wires will work for about a year and then start leaking. OEM wires work forever, or so it seems. My 96 Saturn has over 230K miles on the second set of wires and continue to work well. I'm also a member of a Saturn forum and nobody has ever had good results with "high performance wires" The only alternative is NAPPA wires. Everything else sucks, even Bosch.

You want to grab wires from a S-1 single overhead cam engine. The wires from a twin cam engine S-2 will not work.

For this build, the miata CAS needs to be from 1994-1997. The 1989-1993 CAS may work but the modifications are different. Educate yourself on the two different CAS systems and decide for yourself. It appears that the early CAS is easier to modify but I have not done it.

The 1994-1997 miata CAS is more or less a fuel injected B3 distributor base without a distributor cap. If you look inside a fuel injected Festiva distributor you will see provisions for a second hall effect sensor. Unfortunately the second hall effect parts are not present.

Finding a Miata CAS at a PnP is difficult, but some of you may have luck. Ebay is probably the best bet.

Gather your parts, I'll wait...........

Ok, times up.

Let's build something!

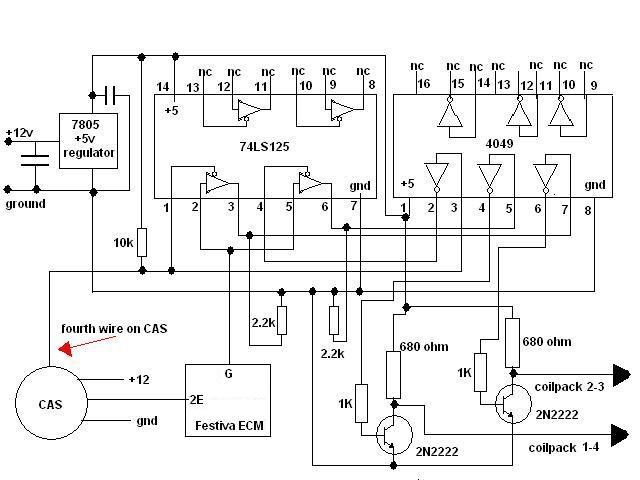

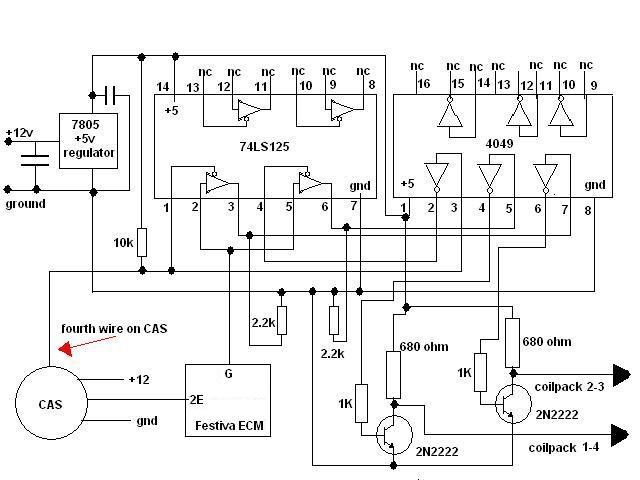

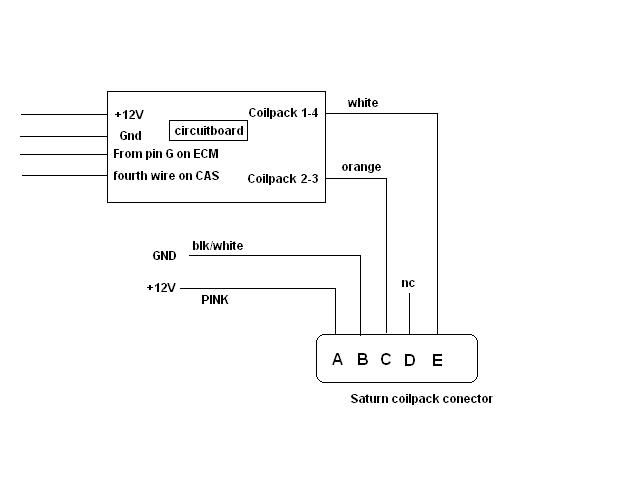

This is the circuit that allows the CAS to work on a Festiva. This is a dumb circuit, meaning it has no intelligence and simply "gates" the signals. The CAS will plug into the Festiva harness without issues, however you will need to add the "fourth wire" The +12V , GND and 2E connections are made by the Festiva harness and are shown for clarity but are not action items.

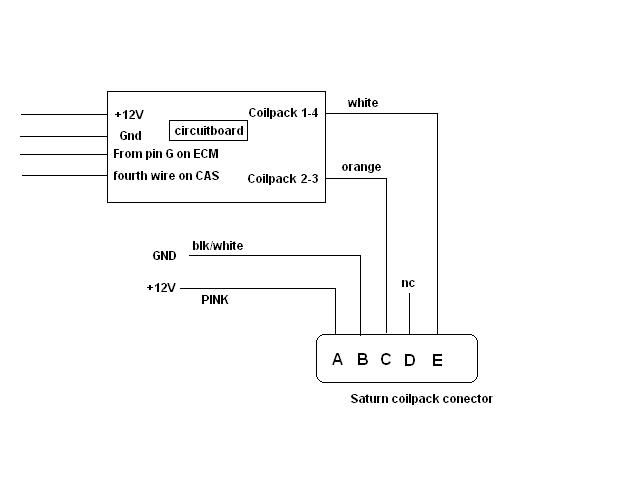

This picture shows how the signals interface with the circuit board and the Saturn coil pack.

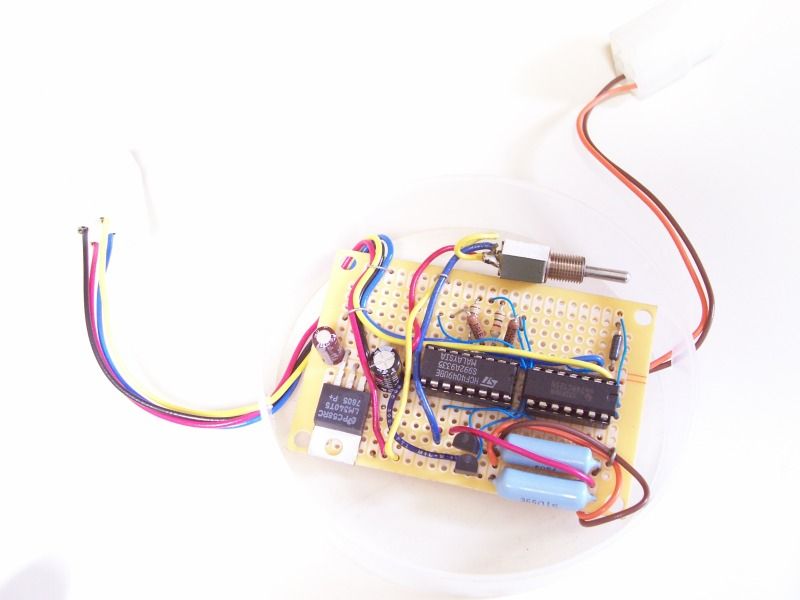

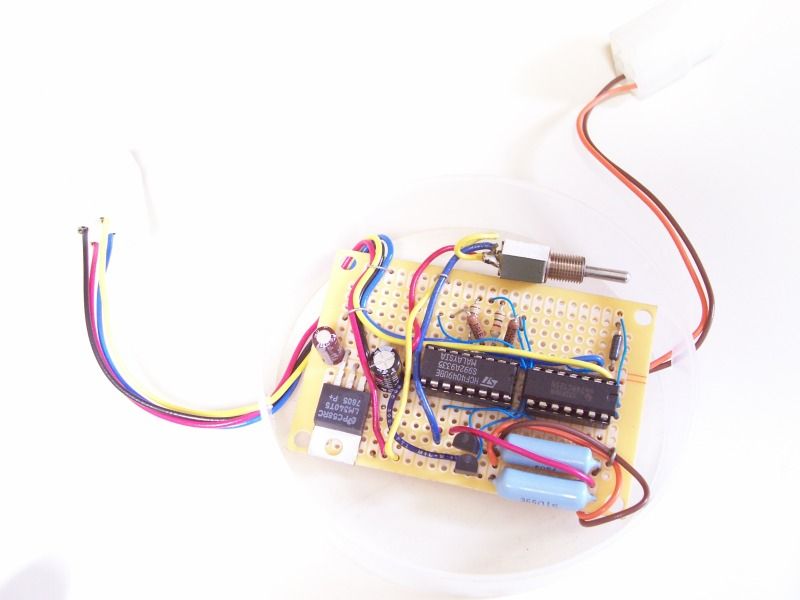

This is the actual circuit board. Its built on a radio shack proto-board. The switch is not required and was used for development.

Continued....

This system may fit other B engines and is not limited to the B3.

Miata CAS (Crank Angle Sensor)

Saturn S series coil pack

Saturn S series coil pack wiring pigtail

Saturn S-1 series ignition wires (single cam engine)

Custom circuit board that you build

New internal CAS rotor that you fabricate.

* Miata CAS wiring pigtail or an extra fuel injected festiva distributor wiring pigtail.

Tools:

Hand tools.

Cutting tools

electrical tools

Dremel with thin cutting wheels.

Soldering iron

files

This system was originally built to work with the stock Festiva ECM and it will work with Megasquirt. Unfortunately I don't know the RPM limit (if any) but it worked well at WOT on the B3. If you have a factory tachometer in your Festiva I dont know if this will upset the tach or if the tach will continue to work.

Before I get into the nuts and bolts of this project, let's talk about parts. Short cuts may be possible but in general you can expect trouble free operation if you use the parts I recommend.

The coil pack should be off of a Saturn "S" series car built between 1996 and 2001. Others may work, but Saturn parts are dirt cheap at PnP. The coil pack that you want to use needs to be "dumb" and needs to have the amplifiers (ignitors) built in.

My car uses 1994 miata coilpacks, but I don't recommend using them. They are expensive and rare. I wired my car to use both the saturn and miata coil packs. I ran the car with both types of coil packs and eventually chose the miata coilpacks because they will allow the Miata tachometer to work.

The ignition wires are important, See if you can grab "stock" Saturn wires from the PnP. Stock wires have "Packard" written on them. Aftermarket wires will work for about a year and then start leaking. OEM wires work forever, or so it seems. My 96 Saturn has over 230K miles on the second set of wires and continue to work well. I'm also a member of a Saturn forum and nobody has ever had good results with "high performance wires" The only alternative is NAPPA wires. Everything else sucks, even Bosch.

You want to grab wires from a S-1 single overhead cam engine. The wires from a twin cam engine S-2 will not work.

For this build, the miata CAS needs to be from 1994-1997. The 1989-1993 CAS may work but the modifications are different. Educate yourself on the two different CAS systems and decide for yourself. It appears that the early CAS is easier to modify but I have not done it.

The 1994-1997 miata CAS is more or less a fuel injected B3 distributor base without a distributor cap. If you look inside a fuel injected Festiva distributor you will see provisions for a second hall effect sensor. Unfortunately the second hall effect parts are not present.

Finding a Miata CAS at a PnP is difficult, but some of you may have luck. Ebay is probably the best bet.

Gather your parts, I'll wait...........

Ok, times up.

Let's build something!

This is the circuit that allows the CAS to work on a Festiva. This is a dumb circuit, meaning it has no intelligence and simply "gates" the signals. The CAS will plug into the Festiva harness without issues, however you will need to add the "fourth wire" The +12V , GND and 2E connections are made by the Festiva harness and are shown for clarity but are not action items.

This picture shows how the signals interface with the circuit board and the Saturn coil pack.

This is the actual circuit board. Its built on a radio shack proto-board. The switch is not required and was used for development.

Continued....

Comment