Hi guys.

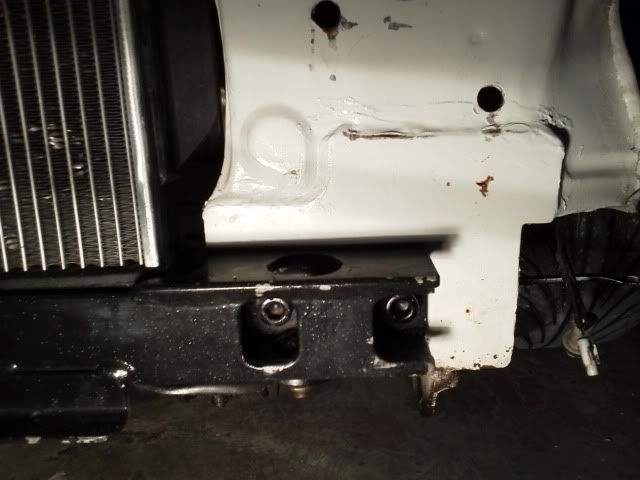

I'm working on my b6t conversion and I've been advice to reinforce the lower rad support while I'm at it.

Do you guys do this because of rust problems? Or is the general structure that weak that it breaks?

I'm also assuming there are a hundred ways to skin this cat. So just to give me some inspiration. If you have done this reinforcement, could you post a pic or two?

If anyone has info on radiator upgrades and best type to use. That would also come in handy.

I'm looking at a civic alloy unit at the moment, but the bottom connector looks like it will clash with the front gearbox mount?!?

Any help is much appreciated! Thanks

Sent from my Galaxy Nexus using Tapatalk 4

I'm working on my b6t conversion and I've been advice to reinforce the lower rad support while I'm at it.

Do you guys do this because of rust problems? Or is the general structure that weak that it breaks?

I'm also assuming there are a hundred ways to skin this cat. So just to give me some inspiration. If you have done this reinforcement, could you post a pic or two?

If anyone has info on radiator upgrades and best type to use. That would also come in handy.

I'm looking at a civic alloy unit at the moment, but the bottom connector looks like it will clash with the front gearbox mount?!?

Any help is much appreciated! Thanks

Sent from my Galaxy Nexus using Tapatalk 4

Comment