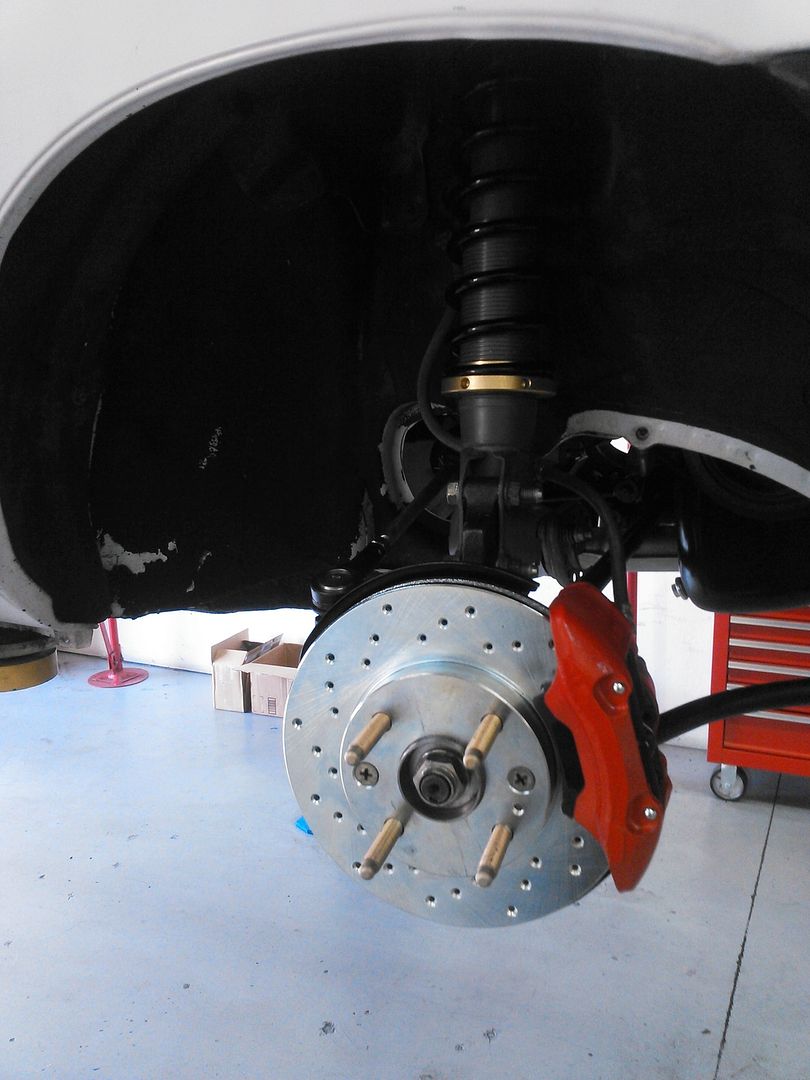

Have any of you guys drilled your hubs and drums for studs? Like a 12mm wheel stud or something like that. It seems like it would be stronger than the wee little stock bolts if you wanted to upgrade to a larger wheel.

Announcement

Collapse

No announcement yet.

Drilling Hubs and Drums for Studs?

Collapse

X

-

Last edited by Advancedynamix; 12-16-2016, 12:34 AM.Driving for me is neither a right nor a privilege. Driving is my passion, as it was for the people who invented the automobile, the people who paved the first roads and the people who continue to improve the automobile. Please respect this passion.

-

All mine use screw in studs. They are strong enough to use on the autocross track.Jerry

Team Lightning

Owner of Team Lightning

90 L "Peewee" B6D. Bought new May 16,1990

92 L Thunder BP G5M-R Turbo B6T electronics. Jan 2016 FOTM winner SOLD

93 L Lightning. BP

Not a user of drugs or alcohol, Just addicted to Festiva's

Comment

-

I used screw in studs on mine...

I went that long because I was using a 10mm spacer. That was my solution for some clearance issues I had as outlined in this thread

I went that long because I was using a 10mm spacer. That was my solution for some clearance issues I had as outlined in this thread

I used shorter studs in the back. If you go this route use a dab of thread locker to secure the studs.Ian

Calgary AB, Canada

93 L B6T: June 2016 FOTM

59 Austin Healey "Bugeye" Sprite

"It's infinitely better to fail with courage than to sit idle with fear...." Chip Gaines (pg 167 of Capital Gaines, Smart Things I Learned Doing Stupid Stuff)

Link to the "Road Trip Starting Points" page of my Econobox Café blog

Comment

-

The press in studs are superior, drill the hole .016 to .020 smaller than the dimension across the splines. An old wrist pin offers good support of the drum or hub when pressing in the studs.

Our cars are light enough to get away with thread in studs MOST of the time, but a crashed car is a lesson I'll never forget.......No car too fast !

Comment

-

Differential expansion, thermal ratcheting, and I promise you red thread locker is a liquid at 600°F. The studs were grade 12.9 hex socket set screws, so when two got loose, the other 3 snapped off.

The cars were fully built World Challenge Touring class racecars, MK5 Jettas, 2.0 gas turbocharged, race weight 3075lbs. (See Avatar)

My fix was to machine the hubs and fit soft (metric grade 9.4) press in studs from an off road outfit in California. No more problems.Last edited by Dragonhealer; 12-16-2016, 02:10 AM.No car too fast !

Comment

-

I use screw in studs as well. I ice race the Festiva, so it sees a lot more force than it normally would on the street, and the studs are stable. I use exactly the same screw in studs in my RX 7, I get them two different lengths from Mazdatrix. I road race the RX7, with 15 inch rims and 205 wide tires instead of the stock 13 inch rims and 175 or whatever tires. Lots and lotsa torque on the road car, enough to pull the rear axles out, but never enough to pull the screw in studs out. And lots and lotsa heat on the front hubs on the RX7, enough to melt the red loctite, like Dragonhealer mentions, and carbonize the wheel bearing grease, but no problem with the screw in studs.

I had a problem one time in the RX7, but it was due to the crappy Chinese made metal in the rotor/hub, where it was so soft the thread in the hub came apart. That one would have failed with bolts too. I knew it was bad but kept my fingers crossed, because there were no other rotors available on the market then. I had bought one and took it back to the store because it was so obviously bad. A year later I was desperate, and bought from that store again and low and behold they actually gave me the same one from a year earlier. It was easy to recognize by the bad machining and spare metal scraps on the bearing races inside the hub. Thankfully I only lost the race and ended up in the tire barrier, not the deep ditch behind the tire wall. Studs would have wobbled loose too, though maybe not as bad, they were made out of that bad a pot metal. Lesson learned: bad Chinese made crap that only looks like a product can kill you, no point in keeping your fingers crossed, better not to go racing, or use those crap rotors you saved for a rainy day. Of course the good rotors probably come out of the same Chinese factory, just a different line for a different supplier.Last edited by Icedawg; 12-16-2016, 12:07 PM.Thricetiva replaced Icetiva as the new ride

Icetiva-3-race-car-build

http://www.cardomain.com/ride/2533299

Comment

-

I think I may go with thread ins for a temporary fix, if I can get the remnants of the bolts out with out drilling them out anyway lol. When I first bought my Festy I was 110 miles away from home and it needed tires. Typically I change tires myself, but being so far from home I paid a shop to put them on and they torqued the hell out of the wheel bolts with an impact. I don't think that they're going to survive the removal process... I figure if I'm going to replace them, I might as well upgrade them in the process.

Comment

-

As an aside, for those of you who have as little interest in Chinese rotors as Icedwag or I, the 1990-1993 Miata rotor is precisely the same as the Aspire rotor, lacking only the two little countersunk retaining holes (which are redundant anyway ) these are made in Japan and available from Mazda for $60 each. If you are using aggressive race pads these are worth it in longevity. AdvanceDynamix has a street combination using Chinese rotors and I think PFC pads which works great, even with weekend warrior track work!No car too fast !

Comment

Comment