Hey guys. I'm installing some new piston rings in a B3 engine block from an '89 L, and I had a few beginner questions about what to expect. I'm using the original pistons, and I had the block's cylinder's honed. I purchased a piston ring set from autozone, and the brand is Sealed Power. I measured the gaps of the first and second compression rings, I got about .018". The manual says the max is .012", but my block has 190k on it, with freshly honed cylinders. I reasoned that this would be mostly acceptable, since I trust the fellow who did the machining, and I just put on all new rings. Should I be alright?

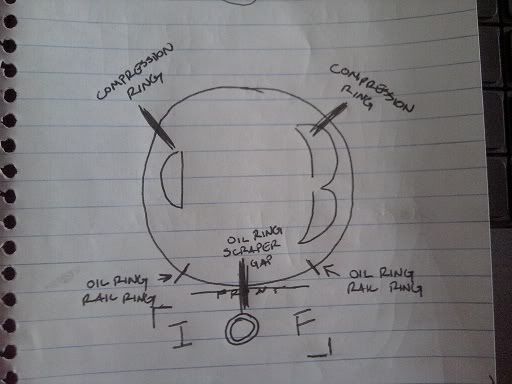

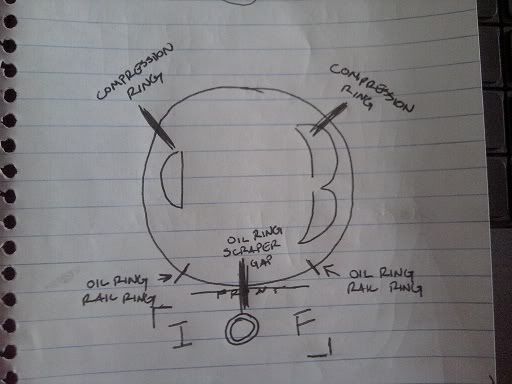

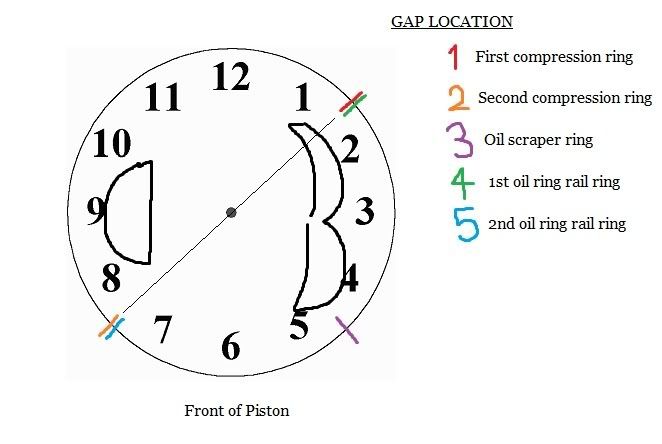

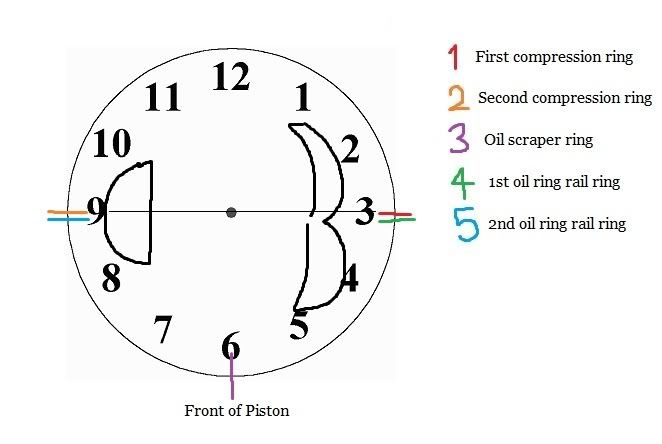

From what the Ford repair manual told me, I came up with this gap diagram:

I dunked the pistons in motor oil, oiled the cylinders, and they fit pretty dang snug. Sliding them down to meet the crank was kind of hard, but not horribly impossible. I installed all four pistons the same way, and they all felt very snug. I can turn the crank from the sprocket with a ratchet, but there is resistance. To make one full rotation, it takes about 15-18 ft-lbs of force (which isn't that forceful by my feel) when the pistons are in the middle of the cylinders.

How am I doing? Google searching just made me worry more, lol

Google searching just made me worry more, lol

From what the Ford repair manual told me, I came up with this gap diagram:

I dunked the pistons in motor oil, oiled the cylinders, and they fit pretty dang snug. Sliding them down to meet the crank was kind of hard, but not horribly impossible. I installed all four pistons the same way, and they all felt very snug. I can turn the crank from the sprocket with a ratchet, but there is resistance. To make one full rotation, it takes about 15-18 ft-lbs of force (which isn't that forceful by my feel) when the pistons are in the middle of the cylinders.

How am I doing?

Google searching just made me worry more, lol

Google searching just made me worry more, lol

I took in the bare bones engine block to the shop, and asked for a 'cylinder hone' and that was about it. My inquiry was pretty generic, since I didn't know about specifics then. The pistons had vertical wear lines on the elongated edges of the piston head, but that was about it. Do you mean tight landings while the piston is in the cylinder?

I took in the bare bones engine block to the shop, and asked for a 'cylinder hone' and that was about it. My inquiry was pretty generic, since I didn't know about specifics then. The pistons had vertical wear lines on the elongated edges of the piston head, but that was about it. Do you mean tight landings while the piston is in the cylinder?

Comment