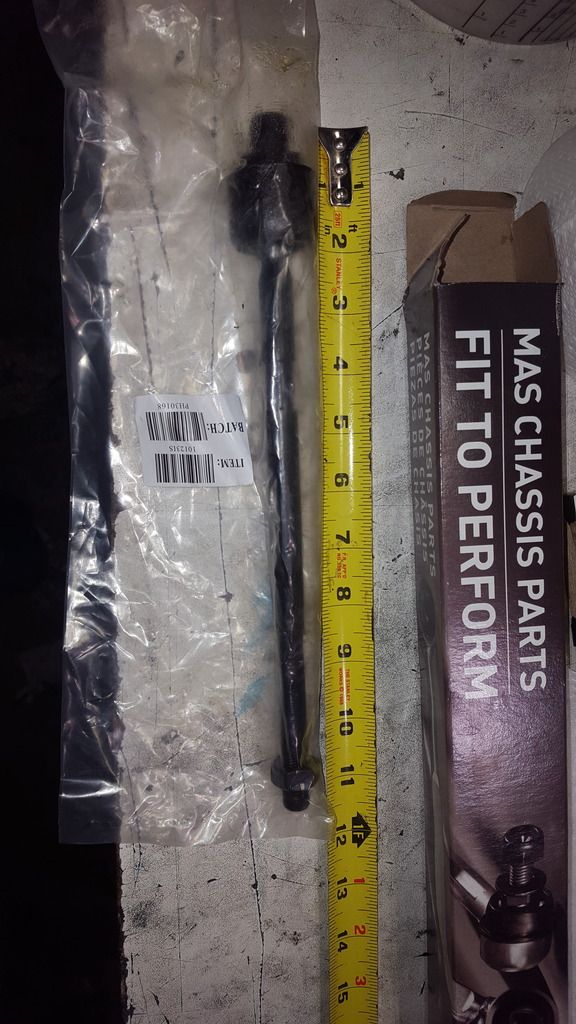

Good comparison pic there, difrangia.

Another way to go about it would be to first thread on a die, then cut off 1/2" off the end of the Aspire tie rod that Detroit Axle supplied, then use the die to fix the threading on the end. If you already had the die and a cutoff wheel, it would be a free fix.

Another way to go about it would be to first thread on a die, then cut off 1/2" off the end of the Aspire tie rod that Detroit Axle supplied, then use the die to fix the threading on the end. If you already had the die and a cutoff wheel, it would be a free fix.

Comment