Well I'm not doing a tranny swap so I think I'm going to go with the Exedy clutch. I'll probably order it tomorrow.

I got my PG today and I do have a few questions, specifically for Iceracer.

How far do I need to deepen the spring pockets to use the green springs? Did you deepen them far enough to use the shorter retainers, or did you still use the longer retainer and just deepen the pockets to prevent coil bind?

I see you mentioned cutting the side gears as well, the PG will not fit if you don't it seems. How much clearance did you leave on each side of the PG between the side gears?

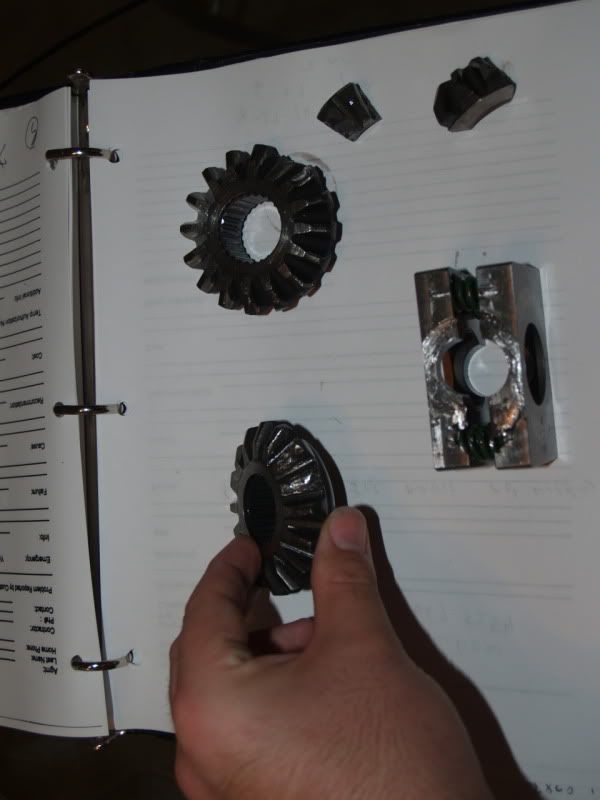

now for some pictures

gold springs and short retainers on left

green springs and long retainers on right

side gears (the smaller ones with the large pin going through them)

4th trans mount to be

I got my PG today and I do have a few questions, specifically for Iceracer.

How far do I need to deepen the spring pockets to use the green springs? Did you deepen them far enough to use the shorter retainers, or did you still use the longer retainer and just deepen the pockets to prevent coil bind?

I see you mentioned cutting the side gears as well, the PG will not fit if you don't it seems. How much clearance did you leave on each side of the PG between the side gears?

now for some pictures

gold springs and short retainers on left

green springs and long retainers on right

side gears (the smaller ones with the large pin going through them)

4th trans mount to be

Comment