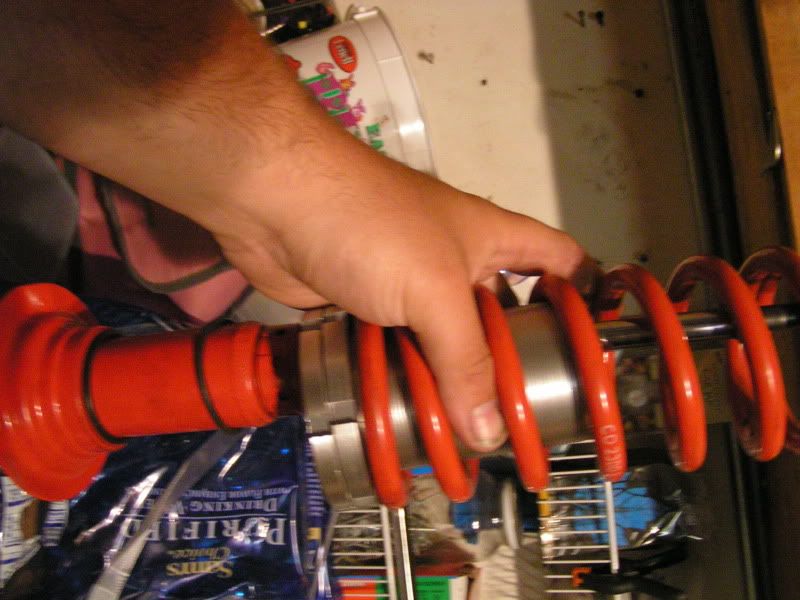

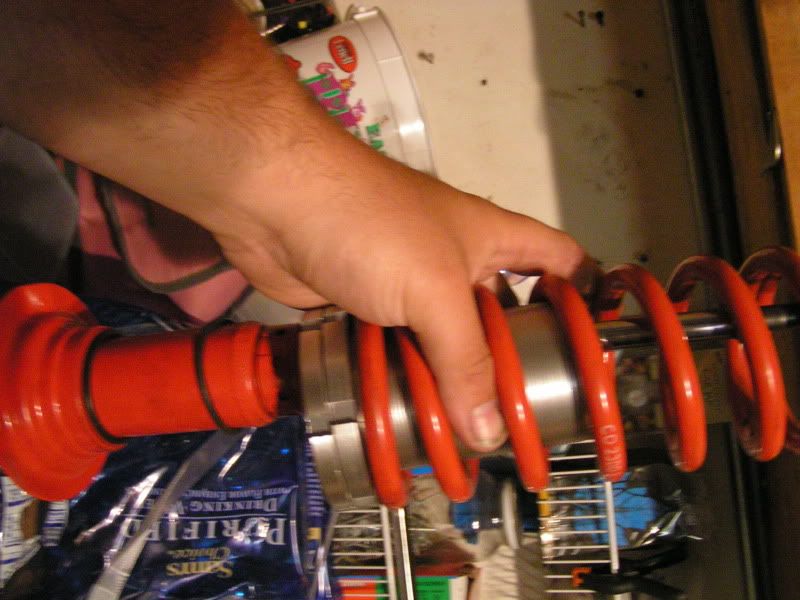

ok so today me and EGTeric pulled the stock festiva rear end and started to assemble the aspire one and get it ready to drop back in. We could not figure out how the coilovers should be assembled and of course there were no directions. i laid out all the pieces on a sheet of paper and put letter by them so give me the order you think it should be in. Also are there any pieces you think i should replace? im going to see if i can find some sleeves tommarow so the bolts fit good in the AGX shocks. I thought there was something that needed to be drilled out? Also im planning on ordering some QA1 shocks what would be a good weight spring for the rear for drag racing? should i get it just as short as the coilover spring?

lets hope they will work... (fingers crossed) and BTW those coilovers and hatch look very sexy

lets hope they will work... (fingers crossed) and BTW those coilovers and hatch look very sexy

i had to do it twice before i got it...

i had to do it twice before i got it...

Comment