I made these struts a couple years ago to test different damper rates and styles. You may notice that the strut extends further down past the mounting ears than normal. This accomplished the same thing as moving the bolt holes down on the knuckle. It worked really really well.

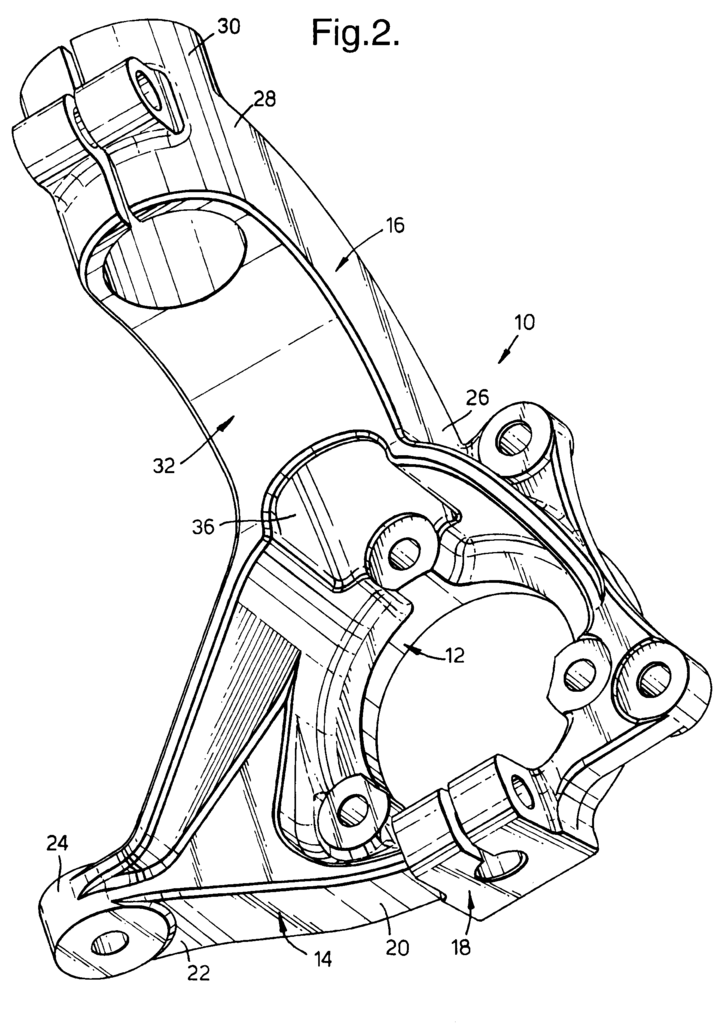

One advantage to shortening the mount flange on the knuckle is that you can run a wider 13" wheel. I want to run 13x7.5 wheels, but they don't clear everything due to them hitting the knuckle in this area. I am using Festiva knuckles on my next street build, because I think they clear the rim better. Aspire hubs will press into Festiva knuckles, but I'll have to use a custom caliper (like Nate explained.)

Comment