I've seen threads here discussing ideas about traction bars and/or compression struts, modification. some to replace the sway bar completely, some to complement the sway bar.

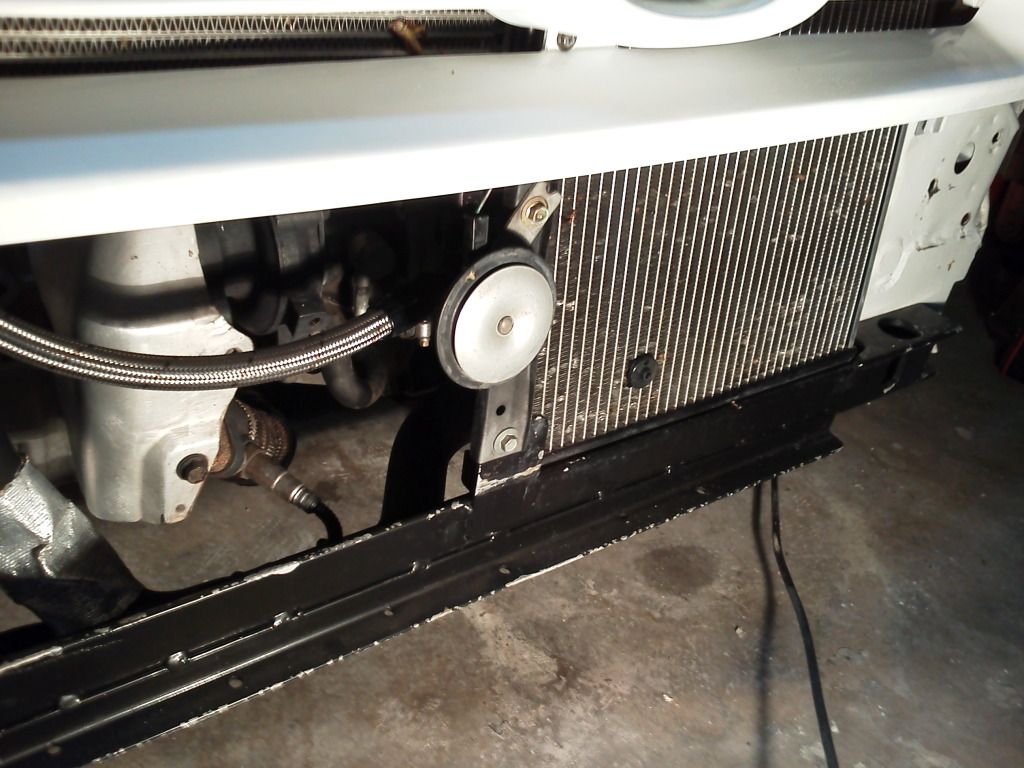

here is my version, utilizing and cutting up the sway bar and attaching the heim joints to it. here is a rough sketch

the goal is to:

1. maintain constant caster alignment(at least getting rid of the front sway bar busings) under hard acceleration.

2. to be able to play around with adjustable front sway bars, or totally doing away with it.

what are your thoughts. anyone see if this is a bad idea for a daily driver/weekend warrior?

here is my version, utilizing and cutting up the sway bar and attaching the heim joints to it. here is a rough sketch

the goal is to:

1. maintain constant caster alignment(at least getting rid of the front sway bar busings) under hard acceleration.

2. to be able to play around with adjustable front sway bars, or totally doing away with it.

what are your thoughts. anyone see if this is a bad idea for a daily driver/weekend warrior?

[/URL]

[/URL]

Comment