That's awesome!!!! Congratulations!!!!!!!!!

When can I come by and see it running?

Announcement

Collapse

No announcement yet.

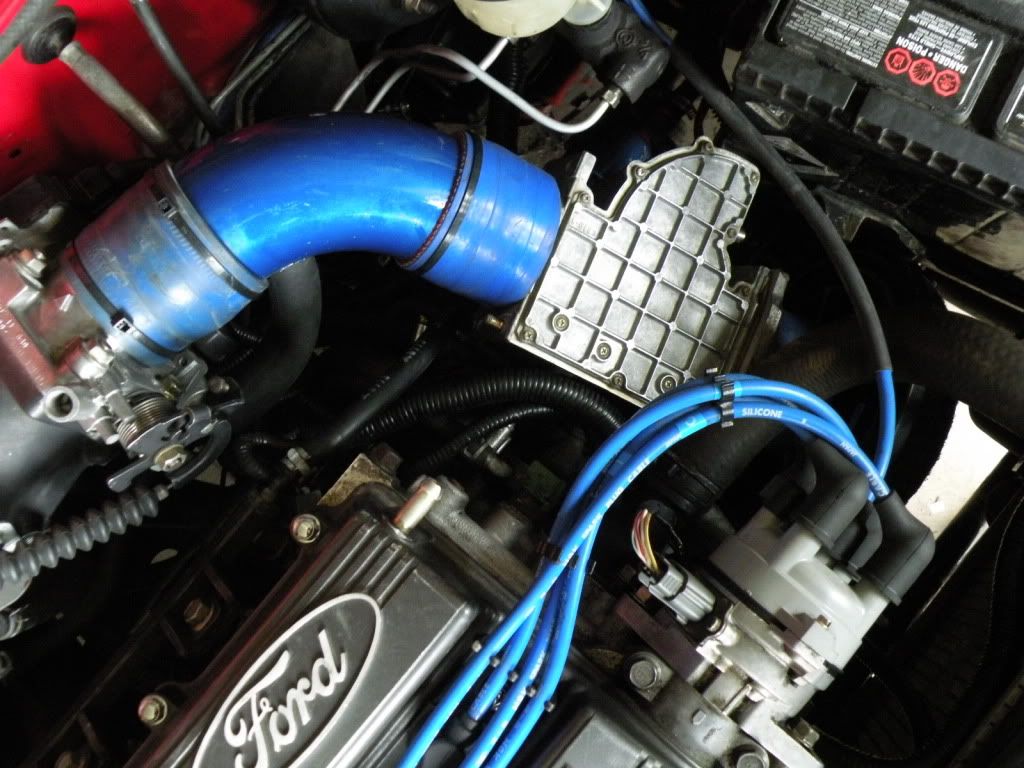

sasquatch's bp swap thread

Collapse

X

-

motor in

exhaust with stock o2 sensor (broken wire...) and wideband

egt gauge port, still gotta stick a sensor in there...

air intake, i know its a crap place to stick the filter cause its sucking in hot air but i couldnt fit it anywhere else

i ran out of bolts that would fit my front trans mount so i was digging around in a box and found some lug nuts that work awesome they are off of an 85 toyota mr2 lol...

they are off of an 85 toyota mr2 lol...

vids!!!!

it sounds better in real life... also it looks slow on film, its faster when your in the car lol...

Leave a comment:

-

ya know... i have been waiting for more vids of your car... ill show you mine if you show me yours lol....

Leave a comment:

-

^ ya i see that, thanks turns out i dint need it that much lol... i figgured it out

turns out i dint need it that much lol... i figgured it out

can anyone guess what i got done today???

pics comming soon

Leave a comment:

-

Nice job on the welds! better than I could do.

I dropped your escort haynes manual off at the front of your door. I was going to call you, but my cell died.

Leave a comment:

-

Originally posted by sasquatch View Post

close up of the welds... do you think they look good? (i wont cry if you say they suck lol)

i dont know why these welds tuned out like crap i was to lazy to make a flange so... lol

i was to lazy to make a flange so... lol

On the first one; Either turn up your wire speed and/or slow down your pass speed just a bit. Also, stop for just a second at the end of each pass. This should help eliminate the undercut. You can turn down the heat just a little but that effects penetration. You've got good penetration, just needs a little more filler. Looks good other than that :thumbup:

On the second: Either slow down your wire or increase your travel speed just a touch and try using a more consistent movement. Maybe try using a Z pattern for your travel or stop for just a second while making your pass to create beads instead of just dragging the head of the gun. Still looks pretty good and doesn't matter as long as it works...LOL

Welding gets much better with practice and MIG welding's biggest variable is getting the machine set correctly.

Leave a comment:

-

Mike .....Why are you having such issues? Do you still have a stock b3 mount laying around? If so put some spacers on the back of the block. Use 3 old tranny bolts. This will help with the alternator spacing too. I didn't have any of these issues, and have been cruising around for 500+ miles in the 80* florida sun with the ac on Get 'er done.

Get 'er done.

Leave a comment:

Leave a comment: