Announcement

Collapse

No announcement yet.

Eurotiva's race garage...

Collapse

X

-

There are examples of this type of intake manifold, some common ones are seen on the dual port VW flat 4 engines as well as some Subaru engines. However, since the dynamics of the intake air are much different than that of the hot exhaust gases there is much less benefit to designing an intake like this. It usually is easier for a manufacturer to build a valuable geometry intake manifold to broaden the tq curve. Horizontally opposed engines make this 4-2-1 design easy to package, so it's more common on them.Originally posted by DriverOne View PostI've got a question concerning intake manifolds in general. I've never seen one go 4-2-1 like an exhaust manifold. I was thinking, would that kind of setup be worth building (an exhaust-style intake)?

Leave a comment:

-

Holy cow Greg that turned out great! drool

I owe you and Dan BIG time for this!

Leave a comment:

-

I don't believe it would work very well. The runners should be seperate due to the individual pulse waves.

Leave a comment:

-

I've got a question concerning intake manifolds in general. I've never seen one go 4-2-1 like an exhaust manifold. I was thinking, would that kind of setup be worth building (an exhaust-style intake)?

Leave a comment:

-

That manifold turned out great!! At least now it points in the right direction lol

Leave a comment:

-

I was thinking about doing that same thing to a Miata manifold, but didn't because the runners point the other direction into the plenum. Not saying this will be a problem because I honestly don't know. I'm very interested in how that manifold works. Nice work by the way!

Leave a comment:

-

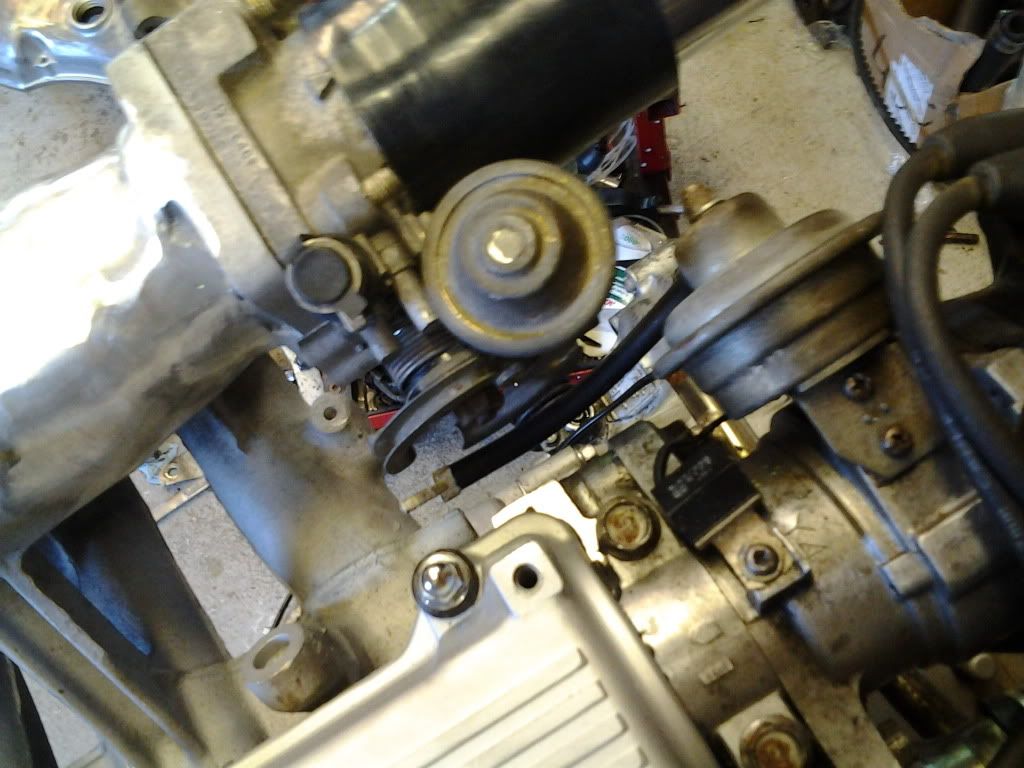

Well today consisted of about 6 hours working on 1 part.

My neighbor Dan (Dan the Man as I call him, and you'll see why) helped me with m3nTalS intake.

And Charlie, we did get the sawzall out lol.

1st we cut this much off of the neck to make more room. We were planning on just moving the throttle body back an inch or two.

Then we got to talking and decided to see what we could do. So this piece got trimmed.....

It looked like it would fit the step that was on the other end of the intake. So the end got cut out. Plasma cutter FTW!

A little bit of grinding and the pieces fit nicely......

Welded a cap on the other end.......

Test fit.............before paint

After grinding and paint..................

I feel good about how it turned out. It'll make routing the piping so much easier.

After doing some yard work, which I forgot to take pics of.. I put a few final touches on Jim's car.

Put in lock cylinder, trunk handle and lights....

And the best mod.........the spoiler !!! +10hp

Productive weekend, and many busy weeks ahead..........

Leave a comment:

-

nice thread. wish i had a place to work on stuff but then i'd need to learn HOW to work on stuff lol.

Leave a comment:

-

When I finish my Architectural degree I'll move back to my 40 acre home place in Virginia (living in PA for work now, headed back to Boston in September) and I'll finish all my projects I've got awaiting me there

Sent from my Nexus S 4G using Tapatalk 2

Leave a comment:

-

Thanks. Dr. I feel fortunate to have a good place to work on stuff

Leave a comment:

-

^^^^ Looking good. wish I had teh place to work on all my stuff like that. one day.... I'm subscribing to this thread now

Leave a comment:

Leave a comment: