I recently purchased myself a 1988 323 Wagon, it has been mechanically converted to a GT with the rear disk brakes, sway bars, and of course the B6T

The plan for it is to get it running and plated with the B6T then later I'll pull it out and swap in a KLG4 with a turbo, 5 lug conversion and get it riding nice and low

It was in the beginning stages of being parted out so it didn't run when I picked it up but was told it shouldn't take too much work to get fired back up again

Here's a few pics from when I picked it up

And a bunch of spare parts to go with it

It also had 4 garbage tires on it which can somewhat be seen in this pic

Before I started putting a face back on it I wanted to test fit my festiva ATH front bumper on it, it fits beautifully if I choose to use it

After a set of tires I was able to roll it out of the garage for a quick photo shoot and to clean up the garage before I get started on fixing it up

My collection of spare parts

First disgnoses showed it has spark but no fuel pressure, so digging further I found out that the fuel pump was dead

So it's a perfect time for an upgrade with a walbro 255lph pump

Along with a new sending unit and gas tank

The old, beat gas tank with the remains of a mouse nest that was on top of the tank

New tank ready to go in

But after getting fuel pressure to the fuel rail, it still won't fire up, checking things out I found out it lost spark..... Ugh

So I didn't bother putting much effort into getting the B6T running since I wanted a KLG4 in there anyway, so I picked up my donor cat

A 2000 626 with a 5 speed

The goods

And it's almost ready to come out

KLG4 is out

Pulled the B6T out

Since I've worked on KL's in tight engine bays before, I counted on having clearance issues with the KLG4 intake/throttle body and master cylinder and since this engine bay has more room in it then my old festiva, I figured if there's enough room to work with, I'll move the engine forward to clear the MC so it was time for a test fit so I can see exactly what I'm working with

And like I anticipated the throttle linkage interferes with the MC

It looks like I can move the engine forward by 2-1/2 inches and I should still have enough room for the rad

The flex pipe on the Y-pipe needed to be replaced so I figured to also add a V-band clamp to make life easier down the road

Hydraulic clutch conversion using GTX parts

When I did the diff swap in the festive I learned of a thickness difference in the ring/pinion gears between the B6T/BP G series vs the KL G series which does not allow the complete internal gear sets to interchange

And since there was a difference in final drive gear ratios I couldn't simply drop in the 26 diff to the KL trans so I ended up separating ring gears and bolting the KL ring gear to the 26 spline diff..... That proved un-reliable in the long run

For this project I don't want to go with an Mfactory because I didn't like how it felt to drive in the festiva so I started using my brain at what options I have to run an open differential and retain the factory rivets

So knowing KL trans either came with a 4.10 or 4.38 final drive, I got thinking about what 26 spline G series had a 4.10 final drive.... The BP trans..... So tonight I picked one up and got to work

After pulling both transmissions apart, I confirmed they had identical final drive gear ratios

The BP ring gear is not as thick as the KL ring gear but I don't think it will cause a problem since the gear ratios match

I was really happy how that turned out so I started the re-assembly

Today I re-threaded the holes in the block for my intermediate shaft mounting plate I made and installed it

When I bought the 626 the owner said it leaked a lot of oil.... So I ordered new valve cover gaskets which arrived today, so I got those replaced as well

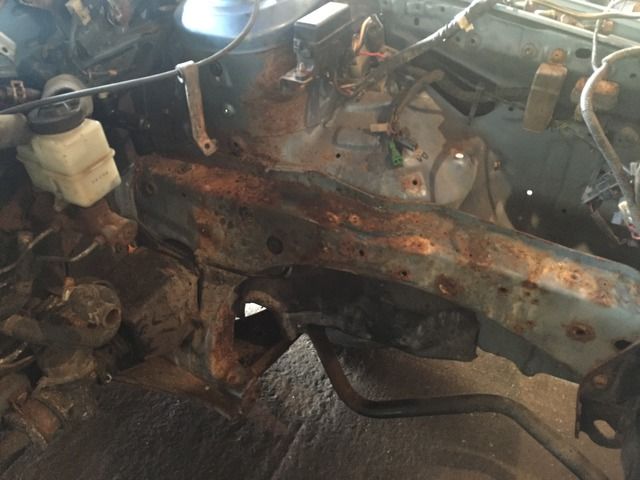

The previous owner of the wagon must have had trouble at some point with the crossmember bolts because the front was welded directly to the lower rad support

So while the engine is out I decided to cut it off so I can make the proper repairs to both the crossmember and the lower rad support

In the process of removing the crossmember I also found the rear bolts were rusted pretty good to the point where I need to basically replace all 4 captive nuts to properly re-attach the crossmember

So today I ground off all the welds on the crossmember, drilled out the mounting holes again (they were full of welds) and re-inforced the ground down areas

Next job is to replace the captive nuts.... ****

The plan for it is to get it running and plated with the B6T then later I'll pull it out and swap in a KLG4 with a turbo, 5 lug conversion and get it riding nice and low

It was in the beginning stages of being parted out so it didn't run when I picked it up but was told it shouldn't take too much work to get fired back up again

Here's a few pics from when I picked it up

And a bunch of spare parts to go with it

It also had 4 garbage tires on it which can somewhat be seen in this pic

Before I started putting a face back on it I wanted to test fit my festiva ATH front bumper on it, it fits beautifully if I choose to use it

After a set of tires I was able to roll it out of the garage for a quick photo shoot and to clean up the garage before I get started on fixing it up

My collection of spare parts

First disgnoses showed it has spark but no fuel pressure, so digging further I found out that the fuel pump was dead

So it's a perfect time for an upgrade with a walbro 255lph pump

Along with a new sending unit and gas tank

The old, beat gas tank with the remains of a mouse nest that was on top of the tank

New tank ready to go in

But after getting fuel pressure to the fuel rail, it still won't fire up, checking things out I found out it lost spark..... Ugh

So I didn't bother putting much effort into getting the B6T running since I wanted a KLG4 in there anyway, so I picked up my donor cat

A 2000 626 with a 5 speed

The goods

And it's almost ready to come out

KLG4 is out

Pulled the B6T out

Since I've worked on KL's in tight engine bays before, I counted on having clearance issues with the KLG4 intake/throttle body and master cylinder and since this engine bay has more room in it then my old festiva, I figured if there's enough room to work with, I'll move the engine forward to clear the MC so it was time for a test fit so I can see exactly what I'm working with

And like I anticipated the throttle linkage interferes with the MC

It looks like I can move the engine forward by 2-1/2 inches and I should still have enough room for the rad

The flex pipe on the Y-pipe needed to be replaced so I figured to also add a V-band clamp to make life easier down the road

Hydraulic clutch conversion using GTX parts

When I did the diff swap in the festive I learned of a thickness difference in the ring/pinion gears between the B6T/BP G series vs the KL G series which does not allow the complete internal gear sets to interchange

And since there was a difference in final drive gear ratios I couldn't simply drop in the 26 diff to the KL trans so I ended up separating ring gears and bolting the KL ring gear to the 26 spline diff..... That proved un-reliable in the long run

For this project I don't want to go with an Mfactory because I didn't like how it felt to drive in the festiva so I started using my brain at what options I have to run an open differential and retain the factory rivets

So knowing KL trans either came with a 4.10 or 4.38 final drive, I got thinking about what 26 spline G series had a 4.10 final drive.... The BP trans..... So tonight I picked one up and got to work

After pulling both transmissions apart, I confirmed they had identical final drive gear ratios

The BP ring gear is not as thick as the KL ring gear but I don't think it will cause a problem since the gear ratios match

I was really happy how that turned out so I started the re-assembly

Today I re-threaded the holes in the block for my intermediate shaft mounting plate I made and installed it

When I bought the 626 the owner said it leaked a lot of oil.... So I ordered new valve cover gaskets which arrived today, so I got those replaced as well

The previous owner of the wagon must have had trouble at some point with the crossmember bolts because the front was welded directly to the lower rad support

So while the engine is out I decided to cut it off so I can make the proper repairs to both the crossmember and the lower rad support

In the process of removing the crossmember I also found the rear bolts were rusted pretty good to the point where I need to basically replace all 4 captive nuts to properly re-attach the crossmember

So today I ground off all the welds on the crossmember, drilled out the mounting holes again (they were full of welds) and re-inforced the ground down areas

Next job is to replace the captive nuts.... ****

Comment