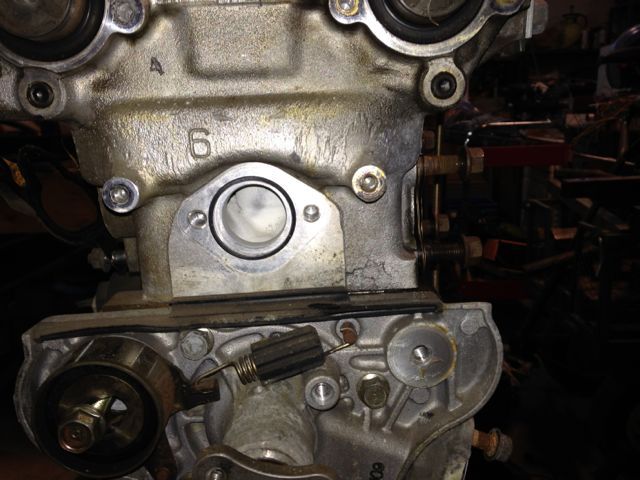

Weekend 11, Finishing off the engine with a new rear main seal from Mazda,

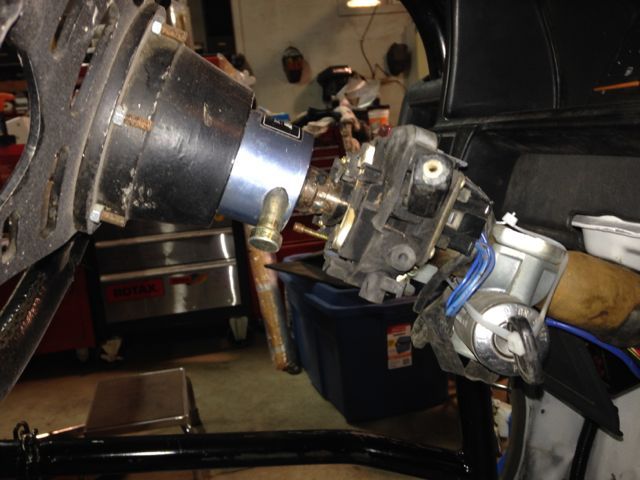

Then the flywheel. The Miata fly on the right is a bit lighter, but I have a nice upgraded clutch on the left for the B6T flywheel, and a fresh grind on that flywheel. The clutch is an ebay F1 company high performance kit.

Turbo is a VJ14/11 hybrid

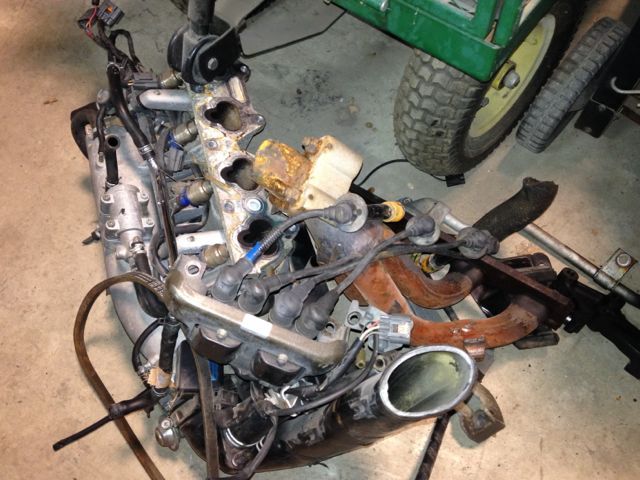

There are so many B6T pieces now on the Miata block that are from the B6T it is clear I could not have made this fit into the Festiva easily without a full long block B6T as a donor. Or a whole lot of real fab work, not the simple swap and minor fab that has taken me long enough to do.

Oil pump, oil pan, intake and exhaust manifolds, turbo of course, distributor, water pump to rad outlet fitting, metal coolant return tubing, coolant return fitting for turbo, engine to rad outlet fitting, turbo bracket mount, front engine mount bracket, interface plate between engine and tranny, knock sensor, crank belt pulley, top of front engine cover and cam backing plate, and valve cover. Probably other stuff too.

Here is what is left of the B6T donor

, but it is built out of lots of past race cars, so the tidy bits come from a long past and legacy of race cars.

, but it is built out of lots of past race cars, so the tidy bits come from a long past and legacy of race cars.

Leave a comment: