Originally posted by bhazard

View Post

Announcement

Collapse

No announcement yet.

Ultimate Street suspension guide

Collapse

This is a sticky topic.

X

X

-

You have to trim them to fit the studs and stay in the correct place. So if you don't get it right in the first try you have to pull it back out and trim it again then it won't stay centered where you want it. Our alignment machine at work will tell you where to trim it and position it but that is only accurate if you're at stock ride height.

-

Awww you suck wanw I've been working all weekend on that lol. Is that for a aspire beam or a festiva beam?

This is for a aspire beam. I was going to have my cousin take it into his college library and print it out. (3d printers are free for student use lol) I want to make sure my dimensions are correct,

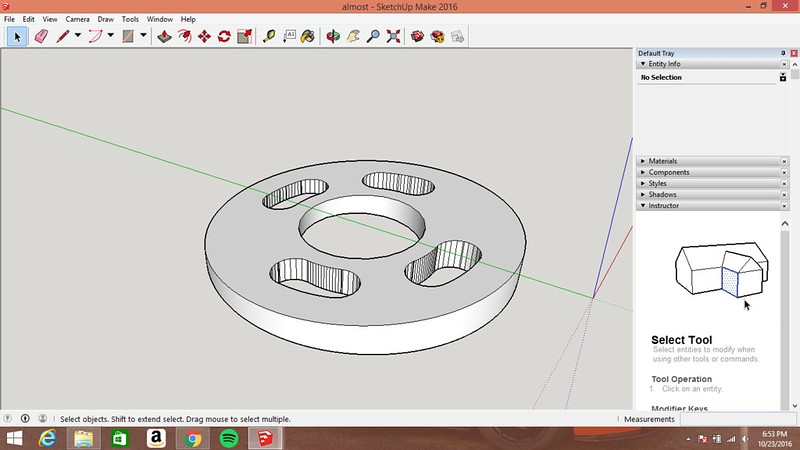

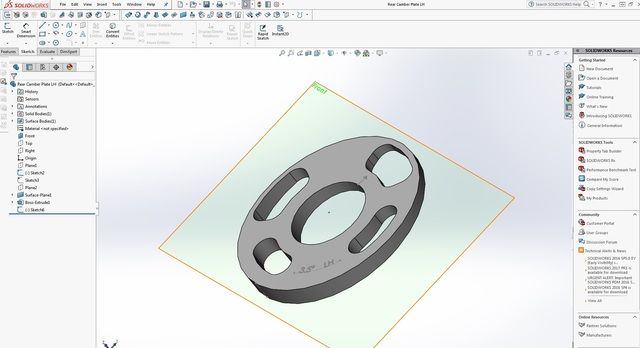

[IMG] Screenshot (3) by Joseph King, on Flickr[/IMG]

Last edited by shorestiva; 10-23-2016, 06:04 PM.

Screenshot (3) by Joseph King, on Flickr[/IMG]

Last edited by shorestiva; 10-23-2016, 06:04 PM.

Leave a comment:

-

-

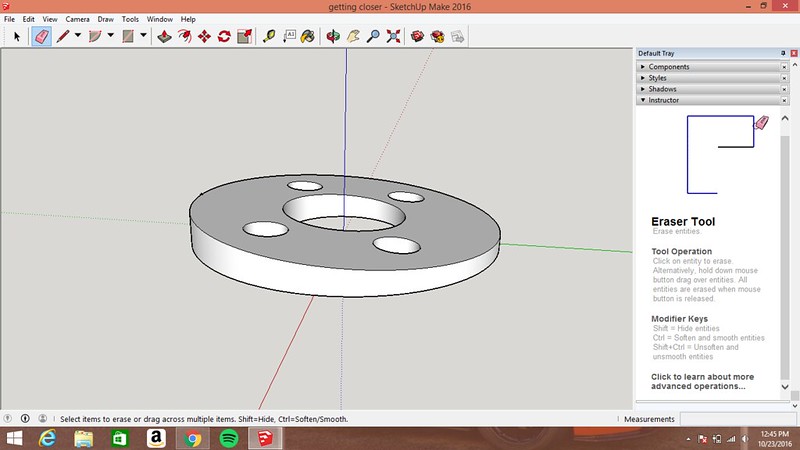

Screenshot (1) by Joseph King, on Flickr

Screenshot (1) by Joseph King, on Flickr

I know the angle is oriented wrong and I have to slot the holes but im getting closer.

Leave a comment:

-

Rear alignment is a pain even with the shims I make. It's just one of those trial and error deals that takes a long time. I never mass produced the shims because they only work if you set the ride height very close to where I have it when I make them. Negative camber translates into toe in as the rear gets lower, the more angle, the more this is true. Also, rake will do the same thing. There is no easy cure for a good alignment in the rear. I would keep a stack of those plastic Moog shims handy if you're going that route. Chances are you'll need to re adjust, and those are a one shot deal.

Leave a comment:

-

^ also why we've been looking into removing the front sway bar all together.

Leave a comment:

-

Having the rear bar would cause more oversteer, not understeer. A stiffer front will cause more understeer. That's why we don't run the aspire front bar.Originally posted by william View PostIf your shooting for 2 degrees swap in an aspire rear beam.

You can remove the Swaybar and make it flex like a festiva beam the aspire axle gives you around 2 degrees negative camber. I had mine on the alinement rack and the rear was 2.2 negative. I think I'm going to remove the sway bar from the rear on mine because when really pushing it the front will under steer but I'm not sure if that's the cause or not

Leave a comment:

-

On the front on mine if you adjust the camber, it has a big effect on toe and you will have to adjust it as well. Something to be aware of. Does this sound right?

Leave a comment:

-

I'm running my car with advanced suspension as well but it's setting as high as possible in the rear . I think you lose cambe and gain toe as it squats right? What I use for an alinement is really a frame rack so it may not be a that accrete .

Leave a comment:

-

I have a aspire beam in mine I only had -1 with the advanced suspension. I spent all yesterday shimming it with washers it's a royal pain in the a** to do. You'll probably end up having to grind down washers to get it close.

Leave a comment:

-

Well that's good to know! I have the aspire beam already. I have heard of people removing the bar from the beam though. I may do this at some point as well.Originally posted by william View PostIf your shooting for 2 degrees swap in an aspire rear beam.

You can remove the Swaybar and make it flex like a festiva beam the aspire axle gives you around 2 degrees negative camber. I had mine on the alinement rack and the rear was 2.2 negative. I think I'm going to remove the sway bar from the rear on mine because when really pushing it the front will under steer but I'm not sure if that's the cause or not

Leave a comment:

-

If your shooting for 2 degrees swap in an aspire rear beam.Originally posted by TWFodor View PostI've seen talk of make-shift rear camber by using washers between the spindle and beam; does anyone know what the outcome of 1/8in washers would be? Or what thickness is needed for -2 degrees camber?

You can remove the Swaybar and make it flex like a festiva beam the aspire axle gives you around 2 degrees negative camber. I had mine on the alinement rack and the rear was 2.2 negative. I think I'm going to remove the sway bar from the rear on mine because when really pushing it the front will under steer but I'm not sure if that's the cause or not

Leave a comment:

-

I was gonna do this! Until i took the rear apart. The rear spindle is held in place by 4 studs. The issue is that the studs are not in line vertically or horizontally. TYou would have to have 4 different thickness washers to make the camber and toe come out right.Originally posted by TWFodor View PostI've seen talk of make-shift rear camber by using washers between the spindle and beam; does anyone know what the outcome of 1/8in washers would be? Or what thickness is needed for -2 degrees camber?

I have bought some shims that are a disk. They are a hard plastic material. You line the shim up to the angle you want and cut holes in it. You take the spindle off and put the big round shim under it. i have shims that are 1.5°. I bought 2 for each side to give me -3°. I will try my best to get the fat part of the shim on the bottom. My goal is to get -3° camber and keep my 0 toe. I have heard that the shims are a pain in the butt to get right tho. Ill look for a part number.

Leave a comment:

-

I've seen talk of make-shift rear camber by using washers between the spindle and beam; does anyone know what the outcome of 1/8in washers would be? Or what thickness is needed for -2 degrees camber?

Leave a comment:

Leave a comment: